Low-cement castable is currently one of the most widely used refractory castables in industrial kilns. Low-cement castable is a type of castable with a small amount of cement added. The production process of this series of castables is quite strict, and there are many factors that affect the performance of low-cement castable, such as ultrafine powder, alumina cement and some other admixtures. In addition, the amount of water added, construction, and grilling are all factors that affect the quality of the castable.

Ultrafine powder is the pillar that determines the performance of low-cement series castables. Without ultrafine powder, there would be no low-cement series castables. Low-cement refractory castables are castables evolved from castable evolution technology. Micro-powder technology has only been adopted in the past decade or so. Ultrafine powder mainly serves as a dispersion accelerator and structural densifier. When cement particles are highly dispersed and do not flocculate, the addition of ultrafine powder can fully fill the micropores of the organizational structure, thereby enhancing the material's strength. However, if the dosage of SiO ultrafine powder(silica powder) add too much, the strength will increase but the refractoriness will decrease. If the addition amount is too small, the fluidity will be poor, which will affect the construction. Therefore, ultrafine powder is a significant factor affecting the quality of low-cement castables.

Aluminate cement plays a setting role in castables. The performance of low-cement castables prepared with different varieties also varies. When the mix proportion and process conditions are basically the same, the dosage of CA-50 cement and CA-70 cement is both 5%. The compressive strength after firing at 800℃ and 1100℃ during drying, the strength of the castable with CA50 cement added is 45-59 mpa, and the strength of the castable with CA70 cement added is 65-74 mpa. It can be seen from this that The performance of low-cement castables made from CA-70 cement is better than CA-50 cement, which is another major factor influencing the quality of castables.

During the construction process, if the amount of water added is too small, the mixture will be uneven; if it is too large, it will affect the setting speed and the strength in the later stage. Therefore, during the construction process, the amount of water added to low-cement castable is also a factor affecting the quality. In addition, during baking, the temperature must rise continuously without turning back. Bake according to the temperature rise curve. If the baking is not done well, it will cause peeling and chipping. Therefore, baking is also a major factor affecting low-cement castables.

Therefore, the factors that affect the quality of low-cement castable must be well controlled during the production process. Moreover, the amount of different alumina cement and their addition amounts should be adjusted according to the usage temperature. So as to produce low-cement castables with good practical application effects.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 15238644201

Phosphating high-alumina bricks involves immersing the finished high-alumina bricks in a phosphoric acid solution for more than two hours in a certain container, followed by…

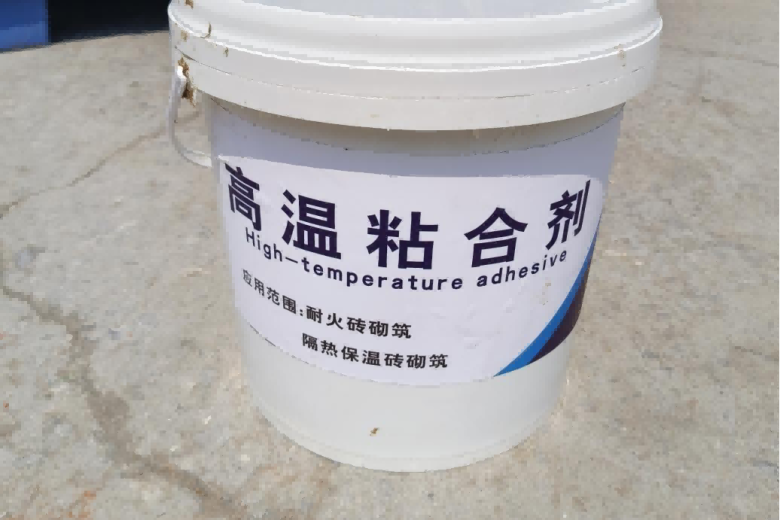

High temperature adhesives are a type of bonding material that can maintain excellent adhesion at high temperatures. They can be used to connect refractory bricks…

Submit Request

PDF Request