Refractory castable drying and baking control process

The difference between silicon brick and semi-silicon brick

Low-cement castable is currently one of the most widely used refractory castables in industrial kilns. Low-cement castable is a type of castable with a small…

When the linear change rate of refractory castables at low temperatures is too large, it will cause significant damage to the castable body and lead…

The matters needing attention during the construction of refractory castables vary with the seasons. The flexible control of on-site construction is very important, such as…

The prices of high alumina bricks of the same material vary. This is mainly due to the differences in body density, shape, and quantity, which…

Both high alumina composite bricks and phosphate composite bricks belong to composite bricks, and the lightweight parts of the composite are both designed to protect…

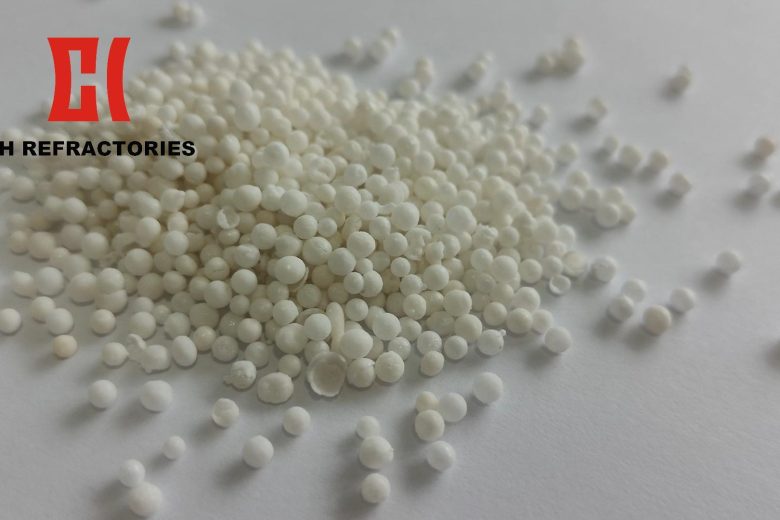

Refractory hollow balls are important raw materials for making high-grade insulating refractory materials. Compared with ordinary insulation materials, refractory hollow sphere products have the characteristics of…

Submit Request

PDF Request