Although there are certain rules for the baking of refractory castables, but there is no fixed value for the baking time. It is carefully controlled based on the actual situation, and the baking time should be determined comprehensively according to various factors such as different types of refractory castables, construction thickness, and usage location.

Whatever refractory castables, refractory bricks, or furnaces mixed with multiple materials, there is a baking principle: slow heating, uniform heating, sufficient insulation, and direct ascent without turning back. The main purpose is to ensure stable water discharge and avoid material bursting during use.

Refractory castables also need to be fully cured and naturally dried before baking, usually for 3 days after construction to ensure sufficient strength after demolding. During the baking process of refractory castables, the temperature should be kept continuously rising for insulation, and there should be no significant fluctuations or temperature drops. If the temperature drops, it will cause damage to the already sintered refractory castables structure.

In general, the baking time for heavy refractory castables is 5-7 days, while for fast drying explosion-proof castables it can be done in 1 day. Plastic castables can be heated up and used with the furnace, but for oversized prefabricated parts and refractory castables with excessive thickness during construction, it should be done in 7-10 days.

However, regardless of the number of days of baking, the most critical period is at room temperature of 150 ℃, which requires slow heating and insulation for up to 24-48 hours to allow the internal surface moisture of the refractory castable to evaporate slowly and evenly, avoiding explosion caused by rapid accumulation of steam pressure.

When the temperature is between 150-350 ℃, the free water of refractory castables needs to be decomposed and dehydrated, and insulation for 24-48 hours is required. When the temperature is between 350-400 ℃, insulation for 24 hours is required. When the temperature is between 400-600 ℃, insulation for 24-48 hours is possible. 600 ℃ is the time period when the crystal water is discharged and begins to form a certain strength. After 600 ℃, the heating rate can be appropriately accelerated before being put into use.

In addition to executing the heating curve, it is also necessary to observe around 300 ℃. If there is still a large amount of steam escaping during this time period, the insulation time must be extended. A clean glass sheet can be used to check whether there is still water vapor condensation in the smoke at the manhole or door to determine.

The temperature difference between refractory castables in winter and summer is significant, and adjustments should be made according to the actual situation.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 15238644201

Phosphating high-alumina bricks involves immersing the finished high-alumina bricks in a phosphoric acid solution for more than two hours in a certain container, followed by…

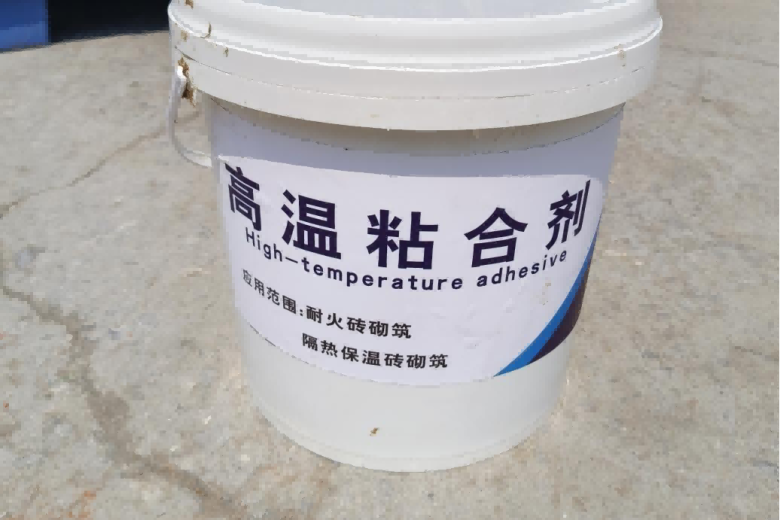

High temperature adhesives are a type of bonding material that can maintain excellent adhesion at high temperatures. They can be used to connect refractory bricks…

Submit Request

PDF Request