Phosphating high-alumina bricks involves immersing the finished high-alumina bricks in a phosphoric acid solution for more than two hours in a certain container, followed by low-temperature treatment, which leads to significant improvements in their physical properties. This enables their use in demanding industrial furnaces.

After phosphating, ordinary high-alumina bricks, as reflected in actual tests, show a temperature softening point increase of over 30°C, a significant decrease in porosity of about 10%, an increase in volume density of 0.2 g/cm³, and a 1% decrease in the flexural strength of the phosphated high-alumina bricks. It is clearly evident that the indicators have improved.

Phosphated high-alumina bricks can enhance their physical properties while also improving their surface micro-roughness and internal structure, enabling neutral products to resist acidic and some alkaline atmosphere erosion.

After being soaked in a phosphoric acid solution for a reasonable period of time and treated at a specific temperature, the phosphoric acid solution penetrates the brick pores, filling some of the air holes and forming a micro-crack buffering structure, which can resist temperature sudden changes and reduce the peeling and cracking of the product under thermal stress impact.

The phosphating treatment of ordinary high-alumina bricks is difficult to operate because the initial product has some stickiness. Without professional containers, the phosphoric acid solution is everywhere, and improper handling can affect the production process and cause the product to get contaminated with the solution.

Our company producing phosphated high-alumina bricks use specially made containers that can hold one high-alumina brick at a time. The entire high-alumina brick is placed in the container to allow it to soak in the phosphoric acid solution. The surface micro-cracks can also heal to some extent, and the internal structure becomes more dense. Then, it is left to stand for 24-48 hours before being subjected to low-temperature baking, enhancing its wear resistance, impermeability, and corrosion resistance.

We have dedicated phosphating equipment, where each high-alumina brick undergoes phosphating treatment and then is heated by the equipment, and each brick is baked at a low temperature. The dedicated phosphating equipment is convenient to use but has more stable performance and better usage effects.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 15238644201

During the construction process of refractory mortar, mixing is an important step. It should be carried out according to the following steps: 1. Cleaning of…

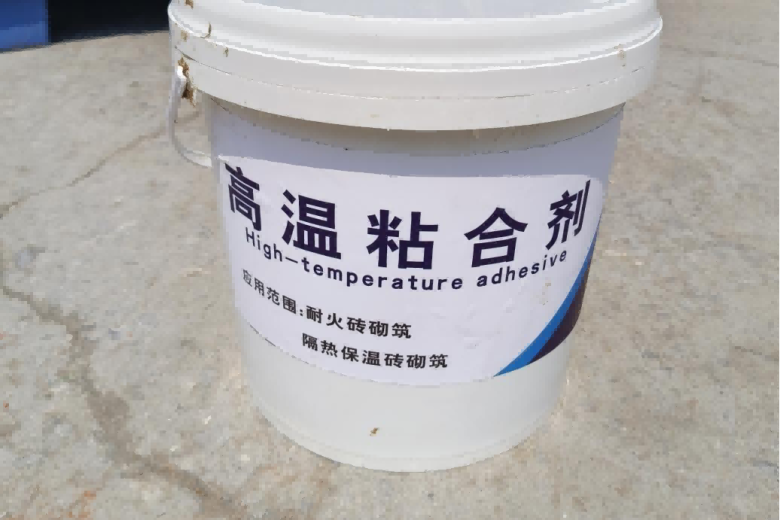

High temperature adhesives are a type of bonding material that can maintain excellent adhesion at high temperatures. They can be used to connect refractory bricks…

Submit Request

PDF Request