There are significant differences between electrically fused bricks and sintered refractory bricks. The differences lie in their production methods, application environments, and prices. The manufacturing method of electrically fused bricks is a liquid-phase reaction. The melt in the electric furnace is completely liquid. The precisely prepared mixture is melted in an electric arc furnace and then cast into shape in a sand mold. The cast block is cooled after heat treatment and then processed.

Sintered bricks are a solid-state reaction, composed of raw materials such as bauxite and corundum. Since both exist in granular form, mullite is formed at the junction of the two during firing. The production process involves pressing into shape with a mixing press, followed by drying, and then sintering in an oxidizing atmosphere at 1350 to 1600 degrees.

When comparing the refractory bricks produced by these two different methods, electrically fused bricks have the advantages of dense structure, very low porosity, high volume density, high mechanical strength and high-temperature structural strength, and strong resistance to glass liquid erosion. The main products include electrically fused mullite bricks, electrically fused zirconia corundum bricks, electrically fused chrome-zirconia corundum bricks, electrically fused quartz bricks, and electrically fused corundum bricks, etc. The density and erosion resistance of sintered refractory bricks are both inferior to those of electrically fused refractory bricks. The main products include clay bricks, high alumina bricks, corundum bricks, mullite bricks, silica bricks, composite silicon carbide bricks, etc.

In the liquid phase of the fused brick, various chemical components are thoroughly mixed and uniform in molecular units, and finally recrystallize. The crystal development is good, and the crystal form can be seen with the naked eye. It is a closed pore, so the erosing agent is not easy to penetrate. The crystals of sintered refractory bricks are very small and invisible to the naked eye, with open pores. Under the condition of using raw materials with the same chemical composition, the quality of crystal production can vary greatly due to the different crystal phases. Because its production process is simple, the selection of raw materials is very important. The production cycle of electrically fused bricks is long, they consume a lot of electricity, the production technology is complex and the price is expensive. The production cycle of sintered refractory bricks is short and their prices are relatively low.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 15238644201

Phosphating high-alumina bricks involves immersing the finished high-alumina bricks in a phosphoric acid solution for more than two hours in a certain container, followed by…

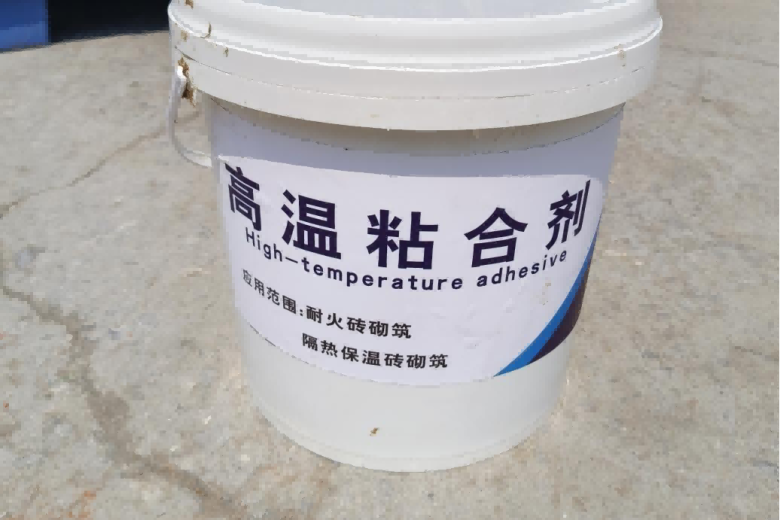

High temperature adhesives are a type of bonding material that can maintain excellent adhesion at high temperatures. They can be used to connect refractory bricks…

Submit Request

PDF Request