The light and heavy composite high alumina brick integrates the functions of the two layers of refractory bricks that need to be laid for the kiln lining, namely the working layer and the insulation layer bricks, on a single brick. It has two sides of the same body, complementing each other's advantages.

The lightweight insulating surface is closely attached to the furnace shell, preventing heat loss and reducing the furnace shell temperature by 50-80℃. At the same time, it can lower energy consumption by 10%-20%. The heavy surface is the working layer that directly contacts the flame, featuring high strength and strong resistance to erosion. The heavy layer and the light layer are formed under high pressure and sintered at high temperature to form a solid whole. It avoids the interlayer separation and sliding caused by the different thermal expansion coefficients of the two materials during masonry. In addition, during masonry, laying a single piece of light and heavy composite high alumina brick is equivalent to simultaneously completing the construction of the working layer and the insulation layer, which improves the masonry efficiency and integrity.

In addition, the specific gravity of the lightweight layer is between 1.5 and 1.9, and that of the heavy layer is between 2.3 and 2.6. The average density is much lower than that of the furnace lining made entirely of heavy bricks, which can effectively reduce the load-bearing capacity of the kiln. It is especially beneficial for large furnace linings and the renovation of old furnaces.

The composite structure of the light and heavy composite high alumina bricks makes the temperature distribution in the furnace lining smooth, which can reduce the thermal stress caused by the large temperature difference of the furnace shell and also lower the risk of cracking and spalling on the hot surface of the working layer. The insulation layer can effectively prevent the furnace shell from oxidizing or deforming when it is exposed to low or high temperatures for a long time. It can extend the service life of the furnace shell. Another advantage is that for intermittent production furnace linings, the heating and cooling rates are faster, shortening the production cycle and enhancing the utilization rate of the furnace.

In conclusion, the light and heavy composite high alumina bricks, after technological improvement, have superior integrated functions and structural stability compared to ordinary high alumina bricks, and are more energy-efficient. Through structural change design, the heat bearing and insulation functions of refractory bricks are perfectly integrated, achieving a unity of energy conservation, structural stability, long service life and convenient construction. It is one of the key materials in the development of long-life furnace linings.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 15238644201

Phosphating high-alumina bricks involves immersing the finished high-alumina bricks in a phosphoric acid solution for more than two hours in a certain container, followed by…

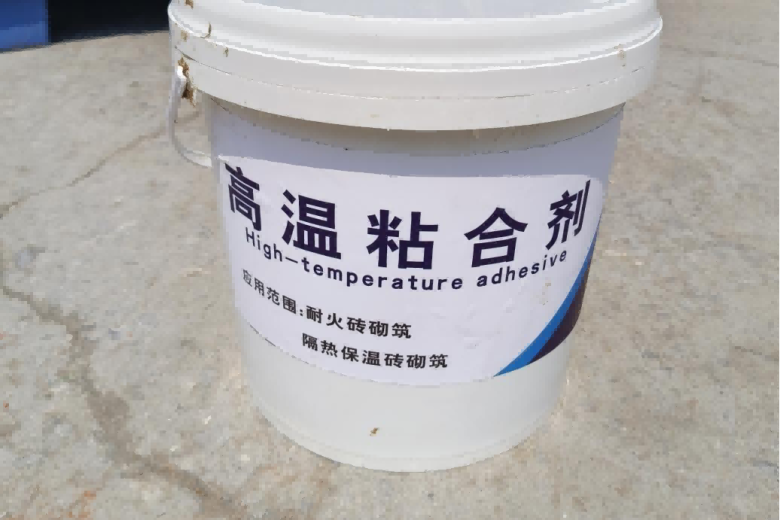

High temperature adhesives are a type of bonding material that can maintain excellent adhesion at high temperatures. They can be used to connect refractory bricks…

Submit Request

PDF Request