The materials for the rotary kiln lining have been constantly updated. It is no longer a simple one-mode lining. Currently, there are refractory brick linings, pure refractory castable overall linings, prefabricated pieces and castable materials each in half for lining, etc.

Moreover, the insulation system is also constantly upgrading, making the kiln skin temperature lower and more energy-efficient. But is it better to make the insulation layer and the working layer as a composite material, or to make them separately? There are various opinions. However, in actual use, the composite method is relatively better than making separate layers for the inner layer.

The use effect of prefabricated pieces and castable materials as linings is better than that of pure castable linings alone, and it is also convenient for construction. However, the insulation layer of prefabricated pieces has different practices from each company, and there are various opinions. According to actual usage, the composite method is better than making separate insulation layers.

Making the insulation layer and working layer as a composite castable material into prefabricated pieces, the reason for the good use effect is that the two working layers are made into a single working layer. During the production process, they are baked at certain temperatures, becoming a single prefabricated brick. Its advantage is that the two layers become one layer, and there will be no disconnection phenomenon. In addition, during construction, the two working layers are completed at one time. It saves energy, manpower and time, and its use effect remains unchanged. Moreover, the overallity is stronger.

Making the insulation layer and working layer separately, or attaching the lightweight insulation part to the heavy working layer, will cause falling or accumulation, or the moisture of the castable material will affect the insulation effect. With the rotation of the rotary kiln, the inner lining of the two layers is not as strong as a combined layer. Moreover, when the fiber board is attached to the heavy layer, and the part of the lightweight insulation material and the heavy working layer are combined, during the baking process, some moisture will overflow, reducing the insulation performance of the fiber board and affecting its insulation performance.

However, in comparison, the composite type overall structure is still more sturdy than the separate or attached prefabricated inner linings, and the construction process is also more convenient and efficient.

Leave a Message

Contact Us

Email: [email protected]

TEL: +86 15238644201

Phosphating high-alumina bricks involves immersing the finished high-alumina bricks in a phosphoric acid solution for more than two hours in a certain container, followed by…

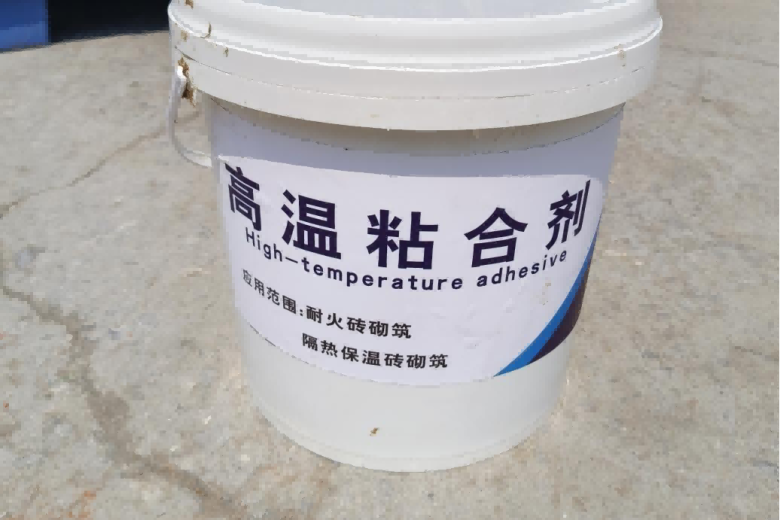

High temperature adhesives are a type of bonding material that can maintain excellent adhesion at high temperatures. They can be used to connect refractory bricks…

Submit Request

PDF Request